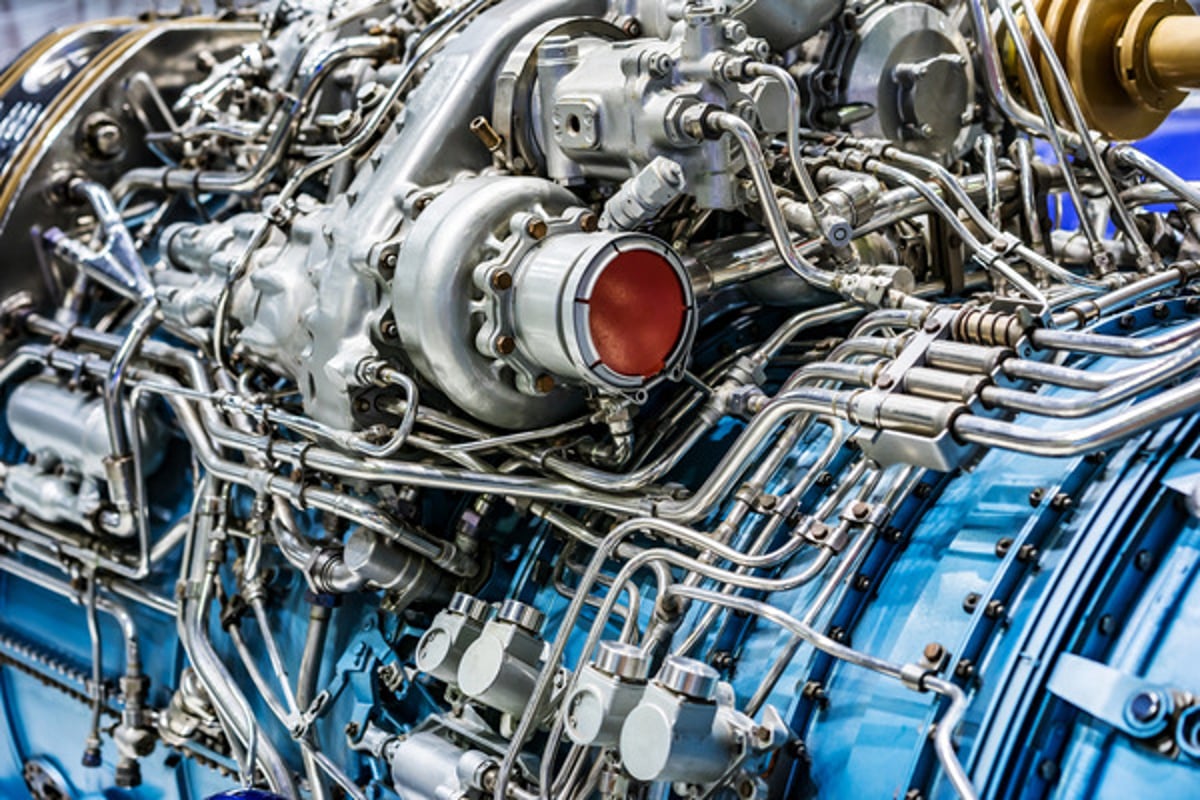

Safe system design and component placement in hydraulics are critical to maintainability and long service life. The proper location of components allows for easy access where they can be readily serviceable. And hydraulic systems are only as good as the components and fluid selection for the application.

Safe system design and component placement in hydraulics are critical to maintainability and long service life. The proper location of components allows for easy access where they can be readily serviceable. And hydraulic systems are only as good as the components and fluid selection for the application.

Strict adherence to Cybersecurity Requirements, AS9100D Certification and Nadcap Accreditation for fittings and other critical hydraulic parts are essential to safe selection during design and maintenance. However, to ensure safe system operation, designers, fabricators, and maintenance personnel must specify the correct fluids to be used (mineral oils, synthetic or semi-synthetic coolants, etc.).

In addition to the right fluid selection, correct placement of fluid filters, hose connections under frequent activation or vibration, and any component that requires frequent changeover or maintenance must be specified0 in the design. Being proactive in the design and fabrication for ease of accessibility to components assures longer system life, reduced maintenance costs and protection of workers. Using 3D-CAD solid modeling and other design software prior to assembly helps fabricators find the best component arrangement.